What is On-Board Diagnostics (OBD)?

A vehicle comprises a gamut of electronic control unit responsible for various functions. For example, an engine control unit manages every function related to the engine and powertrain system. For these ECUs to be fail-safe, they need to be constantly monitored for any faults that might hamper their performance. On-board diagnostics (OBD) is the system that performs this diagnosis and reports any trouble.

OBD-II is the latest version of on-board diagnostics. It monitors and tracks the vehicle’s performance by collecting various parameters from a network of sensors. These parameters are processed by the OBD system and are stored as diagnostics trouble code (DTC) when found beyond acceptable range.

Let’s understand by taking the example of an emission control system. If the vehicle is emitting CO at a higher rate than permissible, the sensor will send a signal to the OBD system. It will store this piece of information in the form of a DTC, specified in the OBD II protocol. Additionally, the OBD system will also switch on the malfunction indication light (MIL) to inform the vehicle user.

What is OBD II software stack?

In order to facilitate a standardized method of vehicle ECU diagnosis and correction of vehicle emission related malfunctions across the geographies, International Standards Organization (ISO) introduced ISO 15031 standard for automotive industry.

ISO 15031 is a standard for Communication between vehicle (OBD port/connecter, defined by SAE J1962) and external equipment (Diagnostic Tester) for emissions-related diagnostics

OBD 2 stack is a set of software specifications or services implemented based on ISO 15031 standard. This OBD II software stack is best suited for passenger car and light commercial vehicle applications

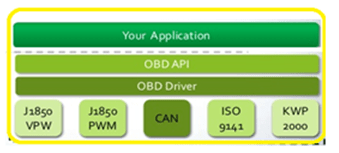

The OBD II stack comprises the following:

- ISO 15031 standard compliant OBD services

- ISO 15765 standard compliant CAN transport protocol (CAN TP) layer

- VPW/PWM drivers to support OBD over J1850

- Drivers for Kline, ISO 9141 and KWP 2000

The following software architecture of OBD II protocol will help understand the protocol better.

Some of the communication protocols (other than CAN) available under OBD II spec:

SAE J1850: There are two variants of this protocol- J1850 PWM and J1850 VPW. The PWM (Pulse Width Modulation) protocol runs at 41.6 kbps. It utilizes OBD connector port pin numbers- 2,4,5,10 and 16.

The VPW (Variable Pulse Width) is slower at 10.4 kbps and utilizes pins- 2,4,5 and 16 of the OBD connector port.

ISO 9141-2 (K-Line): Some European, Asian vehicles implement this communication protocol in the vehicles. It is an asynchronous serial communication and runs at 10.4 kbps data rate. Pins 4,5,7,15,16 are reserved for this.

The image shows an OBD-II Connector:

Pin 2 – J1850 Bus+

Pin 4 – Chassis Ground

Pin 5 – Signal Ground

Pin 6 – CAN High (J-2284)

Pin 7 – ISO 9141-2 K Line

Pin 10 – J1850 Bus

Pin 14 – CAN Low (J-2284)

Pin 15 – ISO 9141-2 L Line

Pin 16 – Battery Power

Types of in-vehicle communications

Vehicle communication can be broadly classified into two:

In-vehicle networking: This refers to exchange of data between various automotive electronic control units (ECU) which are part of the vehicle network.

Automotive Protocols like CAN (Controller Area Network), LIN (Local Interconnect Network), FlexRay, MOST (Media Oriented Systems Transport) are defined for in-vehicle network communication.

Usually this is a broadcast network and one can add listen-only nodes easily.

Vehicle Diagnostics/External communication: Vehicle Diagnostics communication is used for diagnosis and repair of vehicle sub-systems or ECU.

This type of communication is useful for monitoring and reporting of system malfunction monitoring and vehicle parameters. An external tool may be used to re-configure and re-flash the ECU to rectify the malfunction.

Vehicle Diagnostics is a query-response communication. The external tool asks for a particular information (diagnostic request) and the ECU (the control unit to which the query is directed) responds with the answer (diagnostic response)

For diagnostic communication, the physical medium (also known as the signaling protocol) is same as the medium used for in-vehicle communication – CAN, LIN, Flexray, MOST.

Additionally, there are also dedicated protocols like K-Line, J1850 (VPW, PWM) and more that work on serial link. Over these physical layers, diagnostics applications are implemented as per the protocol standards like KWP2000 (ISO 14230), UDS (ISO 14229).

In passenger cars protocols like KWP2000 (ISO 14230) and UDS (ISO 14229) are used as signaling protocols/physical layers, but what data is sent and what conversion factors are used is proprietary to the vehicle OEM (Original Equipment Manufacturer).

Thus, it is not easy to get access to the vehicle data unless one has been granted access by the automotive OEM.

OBD II protocol and Vehicle Diagnostics Communication:

OBD II qualifies as a protocol for vehicle diagnostics communication (query-response communication).

OBD II is a part of emission legislation. Hence it follows the CARB (California Air Resources Board) initiated protocol mandates. OBD II protocol monitors parameters in emission relevant ECUs as per the guidelines of CARB.

OBD II also follows CARB guidelines for data storage and data accessibility to be provided to the external scan tools.

Diagnostic protocols like UDS and KWP2000 support re-configuration and re-flashing of ECU (writing to EEPROM and Flash), but OBD II supports only read access.

The external scan tool requirements (defined in ISO 15031) mandate that the following modes should be supported:

Using Mode $01 and $09, several vehicle parameters become accessible to any external scan tool and the data format is also standardized.

Details of OBD II implementation over physical layers/signaling protocols

OBD protocol has witnessed several revisions (versions update) over the years. Hence OBD protocol still supports various legacy physical layers.

Most of the modern vehicle models implement OBD II over CAN.

Legacy protocols are J1850 (2 variants – PWM, VPW), K-Line and ISO9141-2. Once communication is established in one of the medium, OBD supports query-response communication.

Following are the hardware and software modules for OBD implementation:

| OBD module | Hardware | Software |

| OBD services | NA | ISO 15031 |

| OBD over CAN | CAN support in microcontroller

CAN transceiver |

ISO15765 (CAN TP layer) |

| OBD over J1850 (VPW/PWM) | PWM support in microcontroller

J1850 transceiver |

PWM driver

VPW/PWM driver based on J1850 standard |

| OBD over K-Line | UART support in microcontroller

K-Line/ISO9141 transceiver |

UART driver

K-Line driver (based on ISO14230) |

| OBD over ISO9141-2 | UART support in microcontroller

K-Line/ISO9141 transceiver |

UART driver

ISO9141-2 driver

|

Auto protocol detection is possible to identify which protocol is supported by the vehicle

OBD Challenges/Limitations

- Data available over OBD port (OBD connector) is related to powertrain and emission ECUs’. Hence access to body control data like seat belt status, airbag status and more is not available

- Data is available only in query-response mechanism

- OEMs have option to define proprietary DTCs (Diagnostic Trouble Codes) and not make it available in the public domain. It is also observed that some vehicle parameters are not supported in certain vehicle models. These can lead to compatibility issues

- OBD supports only read-access to emission relevant data (vehicle parameters, DTCs). There is no support for write-access to data for reprogramming or test sensors/actuators. Hence it is not easy to monitor and rectify malfunction related to vehicle functionality (for example engine immobilizer) using OBD communication.

Despite the limitations, OBD is the only option to support vehicle diagnostics applications for a wide range of passenger cars/after-market products already on road.

OBD II is very critical for integrating connected car and telematics solutions for millions of vehicles already on road.

OBD2 diagnostic software development:

Diagnostic Software development for ECU applications

- CAN, J1850. K-Line based OBD2 implementation

- PID and OBD modes implementation

- OBD2 diagnostic software integration with ECU software

OBD2 diagnostic solutions for After-market products

- OBD2 diagnostic software development and integration services

- OBD2 diagnostic services development for vehicle data access

OBD2 solutions for vehicle parameter collections

- OBD2 software design and development services for on-road vehicles