AUTOSAR and ISO 26262 Compliant Model Based Development Services

Model Based Design of Automotive Software

ISO 26262 and AUTOSAR compliant

Complexity of modern automotive software demands development methodologies that save time and ensure reliability. We at Embitel, achieve this by using modelling techniques powered by tools like MATLAB, Simulink and Simscape, and more.

Automation of processes like code generation, testing and documentation lead to faster time to market, something that automotive companies always aspire. Model Based Development (MBD) can result in average costs savings of 25%-30% and time savings of 35%-40% (according to a global study by Altran Technologies, the chair of software and systems engineering and the chair of Information Management of the University of Technology in Munich)

Over the past decade, our team of MATLAB programming experts has been delivering cost and time savings with Model Based Design approach for product development.

Use Cases for Model Based Development of Automotive Embedded Software

Embitel has successfully delivered automotive software developed using Model based design methodology. Our expertise in MBD powered automotive product development spans across the following areas:

Code Generation Using MATLAB as Per ISO 26262 Standard

A Handbook on Model Based Development

Learn about the process of MBD and our capabilities in model based development of automotive solutions

MBD Software Services using MATLAB/SIMULINK

Automotive ECU Modelling

- AUTOSAR/Non-AUTOSAR Compliant Application Layer Development

- MAAB Compliant Modeling & MISRA C compliant Code Generation.

- MIL, SIL and Integration Testing services

- Memory Optimization for RAM/ROM according to MAAB guidelines

- ISO 26262 Compliant Models Rapid Prototyping- Virtual Prototyping, External Bypass etc.

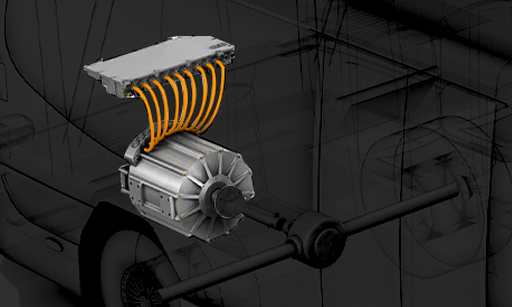

EV Motor Control Development

- Modeling for BLDC motor control for Electric Vehicles

- MAAB, AUTOSAR Compliant Modeling & MISRA C compliant Code Generation

- Development of Motor control solutions for applications like EV Powertrain, Power Steering, Lighting Modules, Seating comfort system and more

Verification & Validation Services

- Model in Loop Testing (MIL)

- Software in Loop Testing (SIL)

- Hardware in Loop Testing (HIL)

- Processor in loop testing (PIL)

- Simulink Design Verifier

- Verification and Validation (V&V) of MATLAB Simulink Models

Automotive ECU Modelling

- AUTOSAR/Non-AUTOSAR Compliant Application Layer Development

- MAAB Compliant Modeling & MISRA C compliant Code Generation.

- MIL, SIL and Integration Testing services

- Memory Optimization for RAM/ROM according to MAAB guidelines

- ISO 26262 Compliant Models Rapid Prototyping- Virtual Prototyping, External Bypass etc.

Migration of Legacy Code to MBD

- Proven Capability of migrating legacy C Code to Simulink.

- Support for Auto-Code generation and Integration Testing

- Deliverables include various compliance report like MAAB, MISRA C

Modelling of LLD and Comm Module

- Implementation of CAN & XCP blocks in Simulink

- S-Function & UI development to configure CAN,XCP blocks

- Simulation & Integration testing of Low-level drivers

Floating to Fixed Point Conversion

- Support for Conversion of Floating point models to Fixed point models as per customer requirements using Mathwork Fixed Point Converter Tool Box.

- Support for Conversion of floating point Matlab code to fixed point code.

- Code generation & testing of floating and fixed point models for the comparison of results, in order to ensure expected accuracy.

Meet Our Automotive Leaders

Sameer brings with him, years of experience in the core automotive software development domain. An ace embedded software developer, Sameer understands the “technical” problems faced by customers really well.

He has been instrumental in several successful automotive control unit software projects and continues to be at the top of his game.Sameer V | Project Manager

(Star Developer of the Automotive Team)

Suresh is no less than an authority in automotive electronics. His years of experience in the domain and a unique ability to provide solutions to complex problems translates into successful projects.

With his excellent leadership quality, he always motivates the team members and strive to bring the best out of them. His knack of understanding the core problems make him the customers’ favorite.Suresh Kumar | Technical Manager

(A people’s Manager)

Customer Success Stories of Implementation of MBD projects

- Model Based Development of Body Control Units

- Model Based Development of Seating Comfort System | Automotive Tier-I Supplier

- MATLAB (Simulink) Based UI Development for Low Level Drivers of Model Based Application

Video Explaining How Model Based Development Works?

Related Blogs & Webinar: Learn More About Model Based Development

- [Video] How a Transition to Model Based Development can Save your Product Engineering Teams from Manual Coding Syndrome

- Why the Transition from Code Based Development to Model Based Development is a Necessary Paradigm Shift in Automotive

- [Video Blog] How Model Based Development Works: A Step-by-Step Analysis

- [Webinar] Model Based Development Tutorial: How to Create Models using MATLAB/SIMULINK

- [Webinar] How to Perform Code Generation Using a MATLAB Model (Part 2 of the Tutorial Series on Model Based Development)

FAQ’s Regarding Model Based Development

Our Expertise in MBD Tools and Technologies

- Target Link for MIL Testing and SIL Testing

- E-coder for code generation

- GT-Power, Amesis, Tesis for Environment Model Development

- ASCET, Statemate and SCADE for functional development

- AUTOSAR ERTL (for AUTOSAR compliant code)

- Custom Target Language Compiler (for customized compilation)

- Vector tools for Hardware in Loop (HIL) Testing

Model Based Development Use Cases

Embitel has successfully delivered Model based software development projects for the following automotive ECUs and other components:

- Body Control Module like Seat Control ECUs

- ADAS (Cruise Control, Anti-lock brakes, ESP etc.)

- Instrument Cluster

- Code to Model Conversions

- Floating Point Model to Fixed Point Model Conversion

Embitel’s Model Based Development Methodology

The Model Based Development V-Model Showing Every Stage of Development & Testing

- Reduced system complexity

- Test suite reusability

- Design reusability to multiple hardware target deployment

- Automatic code generation

- Continuous error identification and correction

- Enhanced efficiency of up to 50%

- Reduced time-to-market and overall cost of development

- Model based development (MBD) is a software development methodology based on V-cycle.

- The model based approach enables a developer to simulate the models for the complex control processes.

These software models can be tested to assess the performance in real-time. Once finalized, the code can be auto-generated from the models, using code generation tools.

This way, the product can be tested at every stage of its development before the code is generated.

Here is a snapshot of Model Based development process:

- Requirement Maturation: Hardware and Software requirement analysis is performed as the first step to weed out maximum number of design issues.

- Model Simulation: The desired functionalities are expressed in the form of mathematical formula which eventually become models using simulation tools like MathWorks Simulink.

- Testing and Validation: Software-in-loop, model-in-loop and hardware-in-loop testing are performed on the model. As it is an iterative cycle, any issue found at any stage is rectified by tracing it back to its previous stage.

- Code Generation: Code is auto generated from the tested and verified models.

- The advantages are many that have made model-driven approach, a method of choice for automotive software development. Model Based Design approach renders a great value-add for development of powertrain and chassis control applications, in particular.

A few of MBD’s advantages:

- Continuous testing of the software at every stage ensures that it is free from bugs/ errors and is of the highest quality.

- Time-to-market is reduced considerably as code doesn’t have to be written manually.

- MBD makes it easier to design Complex functions, as it requires less iterations.

- Cost of development is reduced.

- Test suites can be reused for different production programs.

What software development model do you comply with for delivery of Model Based Development Projects?

- A. Our Model Based Software Development team follow the industry accepted V-cycle SDLC Model. Over the last 12+ years, we have achieved ensured complete compliance and alignment of this V-model with enterprise level QA modules such as

CMMI Level-3

- and

ASPICE

- .

The quality of the artifacts and documents generated throughout the development process are in compliant with CMMI Level-3 and/or ASPICE.

We have also worked on projects where we delivered the artifacts compliant to both CMMI Level 3 and ASPICE, as per the requirements of the customer.

- A. For one of our Model Based Development projects, we developed an

automation tool

- that could convert libraries of

floating point to fixed point model

- . This conversion was the step prior to generating the code and integrating it with the low-level drivers.

Completion of this conversion manually would have taken more than a week for a developer. Also, it would be error prone, as a lot of data type changes and I/O port name changes would have been required.

However, with the help our Automation Tool, we could convert 16 such libraries to fixed point in 1-2 days.

The benefits for the customer were

- More accurate conversion, better quality of the code and very less turn-around time.

- A. Yes, post-integration support is part of the

Service Level Agreement

- (SLA). Any kind of bug fixes and change requests, during or post the integration in production environment are part of our model based design support and maintenance services.

If required, our Model Based Design experts can also travel to the customers’ location for an Onsite Support.

- A. Yes, Embitel has all the necessary skill-sets to help you setup Model Based Software Development process.

- Our MBD experts will help you with the following processes:

- Support for Documentation related to each and every phase of V based SDLC model.

- ISO 26262 compliance

- AUTOSAR based model development

- Test plan, test cases creation

- I/O documentation for every phase of V-cycle as an evidence for CMMI or other QA audits

- A. We have expertise in designing both Non-AUTOSAR as well as AUTOSAR based MBD models.

- Our MBD experts have worked on projects where standard

AUTOSAR

- guidelines have been followed for model creation, data type nomenclature, I/O names, vehicle diagnostics and more.

- A. We can help you with a phased adoption of Model Based Development paradigm after in-depth review of the architecture of your existing product line.

Here is a brief overview of how a MBD adoption/migration approach may turn out be:

- Getting ready for the migration: Includes assessment of current state of the development process and learning the core MBD tools.

- Feature selection as per project scope: Understanding and fin-tuning of scope and requirements at every phase of development, selection of features, modeling and simulation and code generation.

- Component selection and physical modelling: Activities include Expand modelling, simulation at component level and introduction of plant modelling.

- Standardization: Performing Simulation at system level and full model based verification and validation. Best practices like introduction of tool automation and creation of reusable libraries also come into picture.

- Optimization: The final phase is to align the MBD approach with enterprise vision and goals. Objective is to make the processes fully automated and optimized.